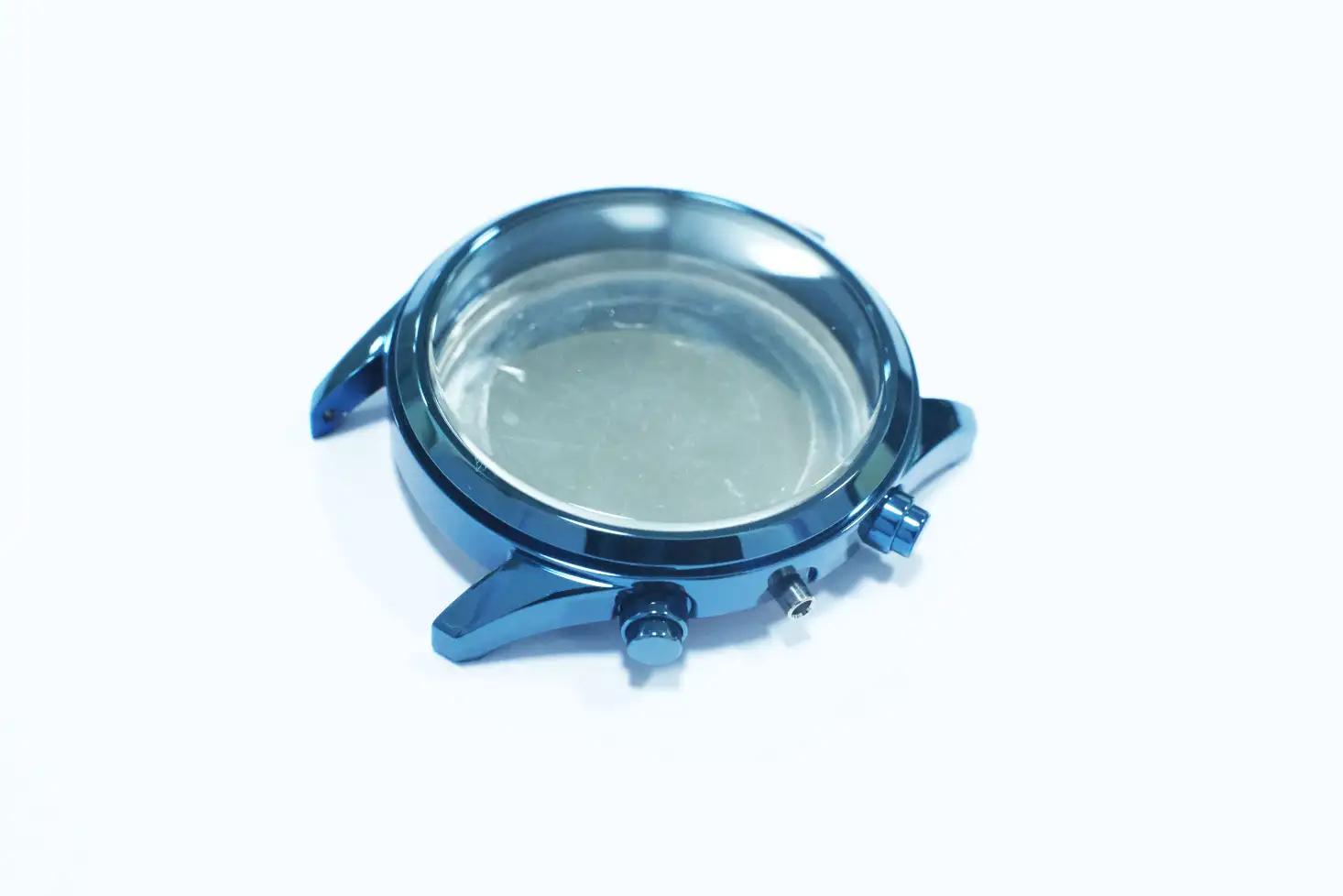

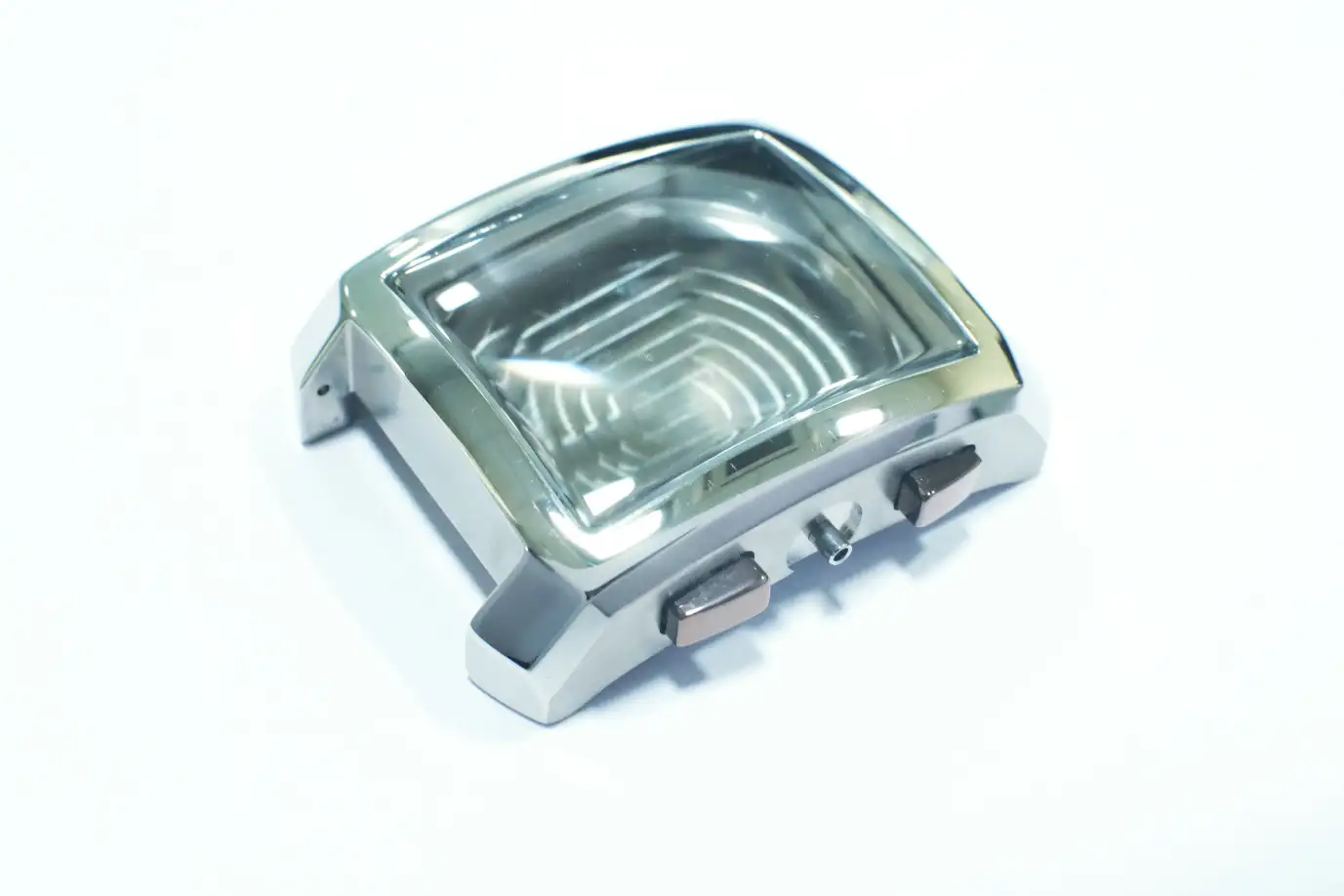

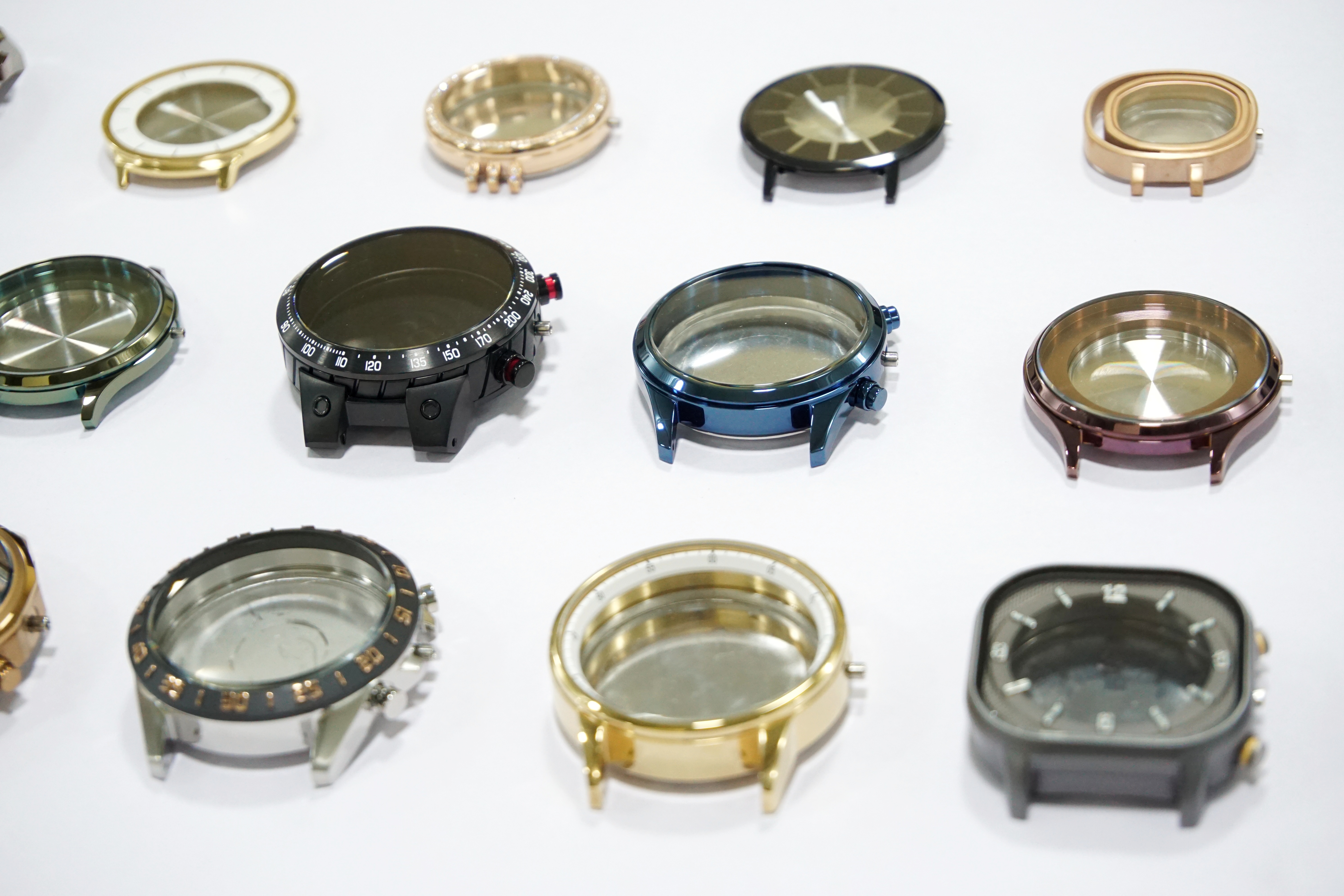

WATCH CASE

The manufacturing of our assortment of watch cases adheres to the same stringent requirements as the rest of our extensive line of high-quality watch components. Our watch case design can be delivered to your requirements in your choice of style, material, and finish to offer the best possible component for your product.

As one of the most seasoned stainless steel watch case suppliers, we craft our own manufacturing facility's watch cases to the highest standards using cutting-edge technology, including medical grade dust-free environments. Our watch case production also combines with our expert logistical support for trusted component supply for all your critical watch components.

HOW ARE WATCH CASE MADE

The majority of watch casings are produced using a technique called subtraction manufacturing. In other words, the case is sculpted by removing material from the block to reveal the case structure itself. The case begins as a sheet of metal formed to its basic shape of material, whether it be stainless-steel or another metal.

While some of this procedure is carried out manually using a lathe, the majority is done using a multiple-axis CNC machine under computer-driven control. Because of the extremely fine tolerances for consistency and precise component fit during watch production, this guarantees that every case will be the desired size and form.