"Our master craftsmen-Titanians make world-class products through the Art of Horology."

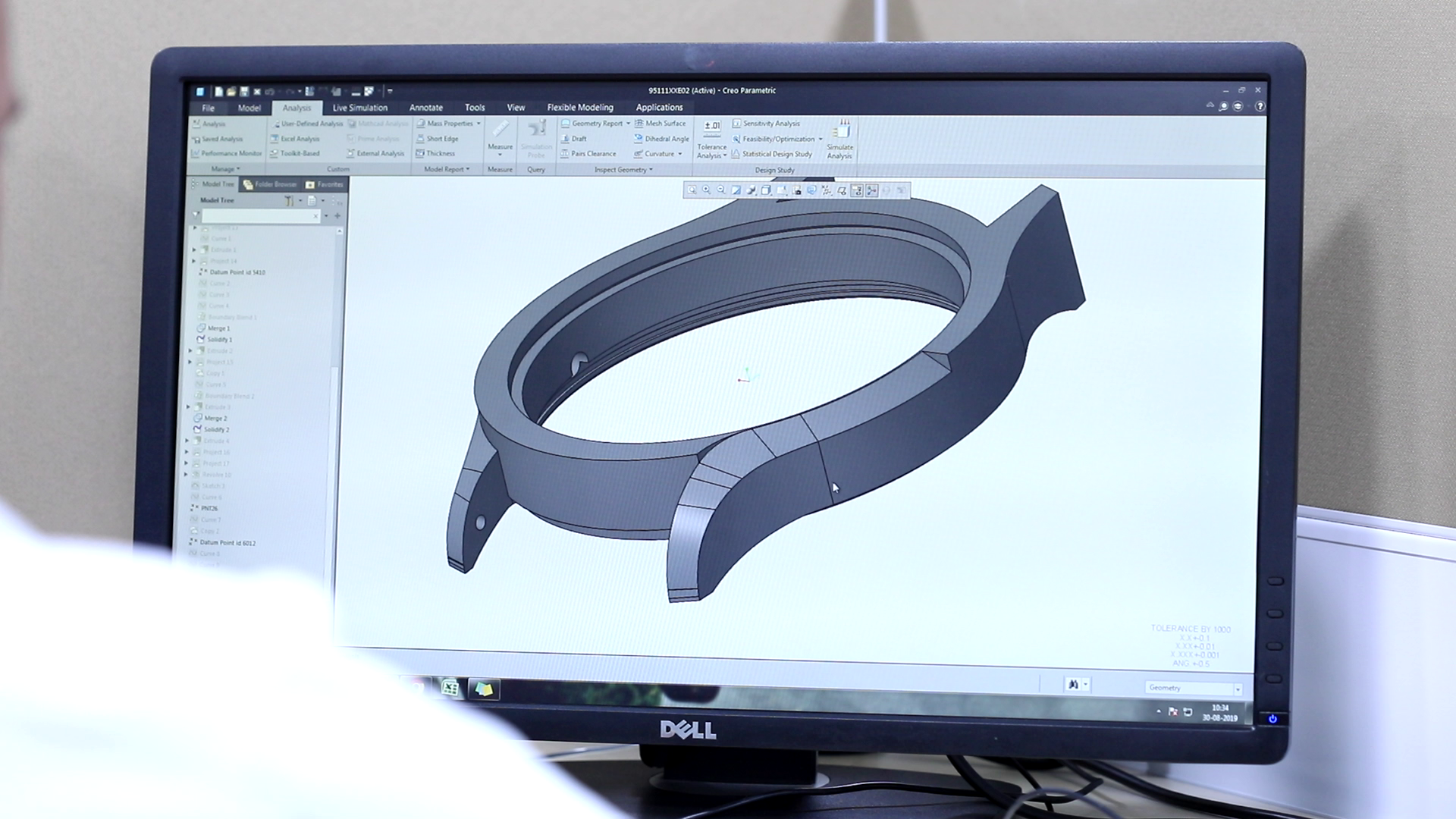

Product Design

Our product design team has decades of experience in watch designing. Our team creates a virtual product using CAD software, such as PTC Creo and AutoCAD. With the help of the 3D model we create, it would be possible to visualize the final product. We also perform DFMEA analysis for the products at the design stage itself and identify the product, process failures even before the product is manufactured.

New Product And Capability Development

This department develops new products and they work closely with the technical team to monitor the development process. The department is also responsible for expanding the capability of our product portfolio.

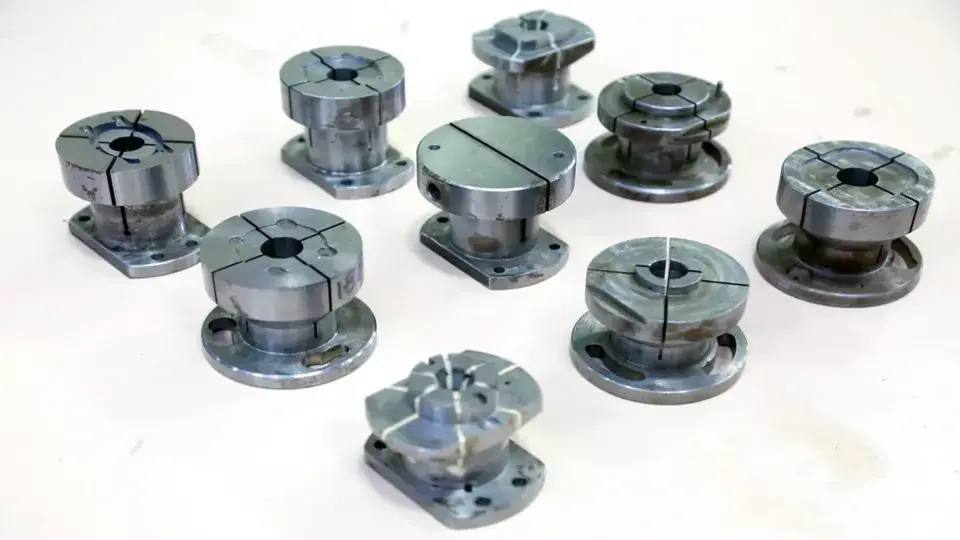

Tool Design And Manufacturing

Our Tool Manufacturing department runs on unconventional manufacturing processes such as Wire Electric Discharge Machining (WEDM) and Spark Electric Discharge Machining (SEDM). All the tools required for the watch manufacturing process, including but not limited to the Stamping tools, Jigs and Fixtures for machining, polishing and assembly, are manufactured in-house.

Stamping / Press operations

The Press Shop produces components with near net shape. I equipped the Press Shop to handle tonnage ranging from 25 to 300 tonnes. Majority of our components are cold forged. The press uses single minute exchange of dies for reducing the tool changeover time. We also use progressive forming to reduce the total number of forming cycles it undergoes in the normal forming process. We are equipped with an annealing heat treatment facility, which improves ductility by reducing the work-hardening component.

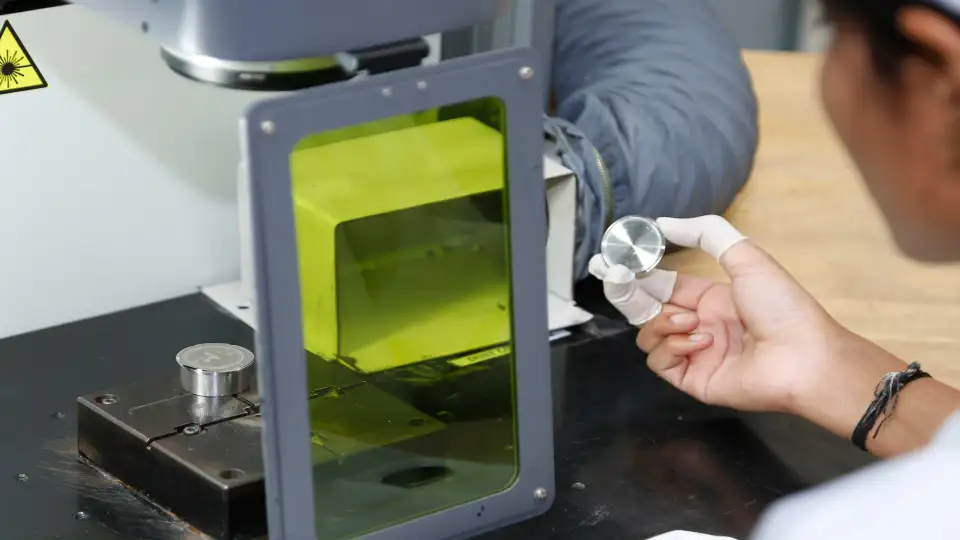

Machining

The Machine Shop is equipped with advanced state-of-the-art, 5-axis German and Japanese machineries to machine the components with high precision and accuracy to the level as low as 10µm. Processes such as Turning, Milling, Drilling, Tapping, Engraving and Knurling are performed in the Machining department.

Polishing

The Polishing Shop is capable of producing a variety of finishes like Mirror, Brushed, Matt & Sand-blasted. Single finish & Multi finishes in a single component are also possible to achieve. The Polishing Shop handles special operations like cermet-cutting to achieve diamond-cut finish. We use contemporary technology to produce excellent finish in the products by incorporating advanced techniques like plasma polishing. Skilled workforce achieves the expected level of versatility and quality.

Assembly

This is the place where fixing of case pipe, push button, glass, back cover, decorative inserts and add-ons are carried out. Once the assembly is completed, the watchcases are carefully tested for water resistance before they moving the next stage. Watch assembly is carried out in a lint and dust free condition. Micro engineered parts from different departments are assembled and tested here to produce a world-class timepiece. Assembling of micro precision parts is done with the help of automated machines and testing equipment in a sequence.